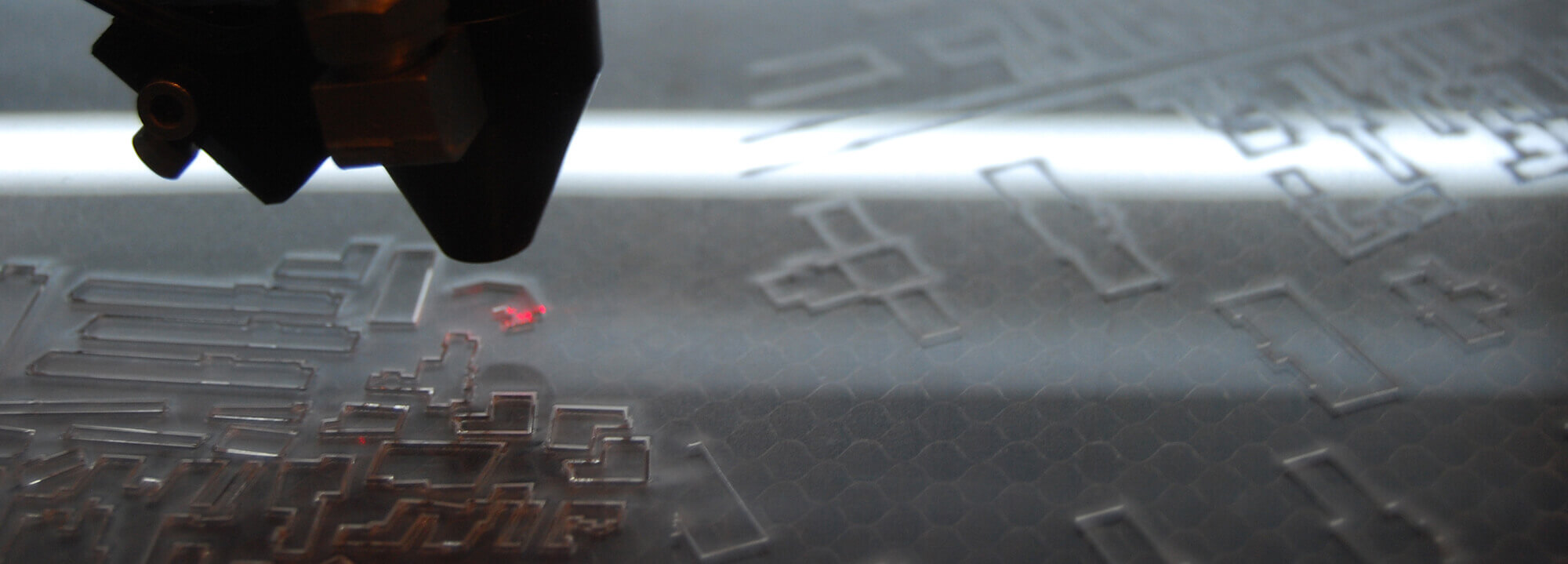

Laser technology offers the fastest cutting, engraving, and photo engraving methods on the market for a wide range of materials. Compared to traditional processing technologies, laser processing ensures a much higher level of detail and the ability to produce much smaller pieces.

At “Atelier 13,” you can benefit from the advantages of this technology either independently, by ordering laser cutting and/or engraving services, or by ordering production and/or design services for items whose optimal execution method is represented by laser processing.

The use of laser technology for material processing is widely applicable in various fields due to its accessibility and speed. Laser processing can easily produce custom-designed pieces or objects when there’s a processable material and a 2D vector drawing to guide the processing.

In our workshop, you can confidently rely on the advantages of laser technology when you want to cut or engrave suitable materials to obtain small pieces with fine details, large or small pieces with thicknesses up to 10 mm (depending on the desired material), or pieces from flexible or fragile materials that would not be suitable for traditional mechanical cutting methods.

The fields of application for laser processing are numerous, ranging from creating custom objects for all creative industries – architecture, design, fashion, art, advertising, scenography, and handmade creations – to producing pieces or sub-assemblies for advertising production, presentation models, or engineering prototypes.

The main characteristic of laser cutting is the darker color of the processed material’s edge, with the exception of plastic materials that do not change their shade after processing.

We recommend that for solid pieces, without holes, their minimum dimensions should be larger or equal to 5×5 mm. For those of the fretwork type, with holes, the distance between the holes should be greater than 1-1.5mm, depending on the chosen material.

The thickness of the laser beam when cutting is comparable to 0.2mm, depending on the chosen material.

Line engraving is the process of marking materials with a line design. The outcome is similar to pyrography but with a much higher degree of precision and detail.

Line engraving can be done at different thicknesses and depths which are however relative, being only comparable to each other, not measurable.

The most visible line engravings are made on wooden or cellulosic materials, these resulting in a darker color than the surface of the material.

Surface engraving is the process of covering a surface with a succession of horizontal line engravings, very close to each other. Increasing the density of the engraving lines, translated by increasing the engraving step, leads to a uniform covering of a surface but also to an increase in production time.

The color changes in the material during processing will primarily be evident in wooden and cellulosic materials, even though there are also certain plastics specifically designed for surface engraving.

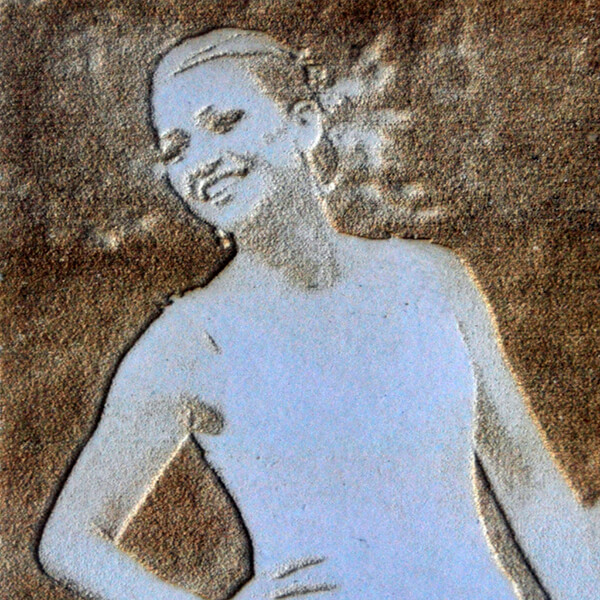

Photo engraving is the process of creating gradient surface engravings based on black and white images with very good contrast. The result obtained from laser image engravings will always be a slightly abstracted version of that image.

The quality and appearance of the photo engraving depend both on the resolution and contrast of the model image as well as on the behavior of the supporting material.

The most successful photo engravings can be made on wooden and cellulose materials, but also on a series of plastics specially designed for engraving.

| CATEGORIES | MATERIALS | THICKNESSES | CUTTING | ENGRAVING |

| PLASTIC | acrylic sheets ( plexiglas ) | 1.5, 2, 3, 4, 5, 6, 8, 10 mm | ||

| acrylic sheets ( plexiglas ) | >10 mm | |||

| copoliester PETG | 0.5, 1 mm | |||

| hips | 1, 1.5, 2 mm | |||

| ABS – laserable | 0.5/0.8, 1.3/1.5, 1.6 mm | |||

| forex or PVC | alll thicknesses | |||

| WOODEN MATERIALS | MDF | 3, 4, 6, 8 mm | ||

| MDF | > 8 mm | |||

| birch plywood | 1, 1.5, 2 mm | |||

| poplar plywood | 4, 6, 8 mm | |||

| plywoods other essences | 4, 6 mm | |||

| plywood in general | > 6/ 8 mm functie de esenta | |||

| balsa | 1, 1.5, 2, 2.5, 3, 4, 5, 6, 8, 10 mm | |||

| cork | 1, 2, 3, 5 mm | |||

| cork | >5 mm | |||

| CELLULOSIC MATERIALS | paper | 0.3 – 0.8 mm | ||

| duplex | 0.5 – 0.8 mm | |||

| cardboard for bookbinding | 1, 1.5, 2, 2.5, 3 mm | |||

| passepartout | 1.5 mm | |||

| corrugated board | 1.5, 3, 4, 6.5 mm | |||

| foam x | 3, 5 mm | |||

| METALS | steel * | – | ||

| etchable anodized aluminum | – | |||

| OTHER MATERIALS | textiles * | – | ||

| felt * | 1.5 – 3 mm | |||

| natural leather * | 0.5 – 1.5 mm | |||

| thin sponge * | <10 mm |

non-existent materials in Atelier 13 stock

To place a laser processing order, you need to send us a 2D vector drawing of the desired pieces, scaled 1:1 in mm, in which you mark with different colors the types of processing used – cutting, line engraving, or surface engraving.

For ease of communicating the desired result and to avoid interpretation problems, we recommend using the template below, which can be imported to scale in any vector drawing software.

We recommend taking into account the following special mentions regarding file preparation:

After analyzing the files and project requirements, you will receive our offer based on material consumption and on estimating the quantity or processing time.