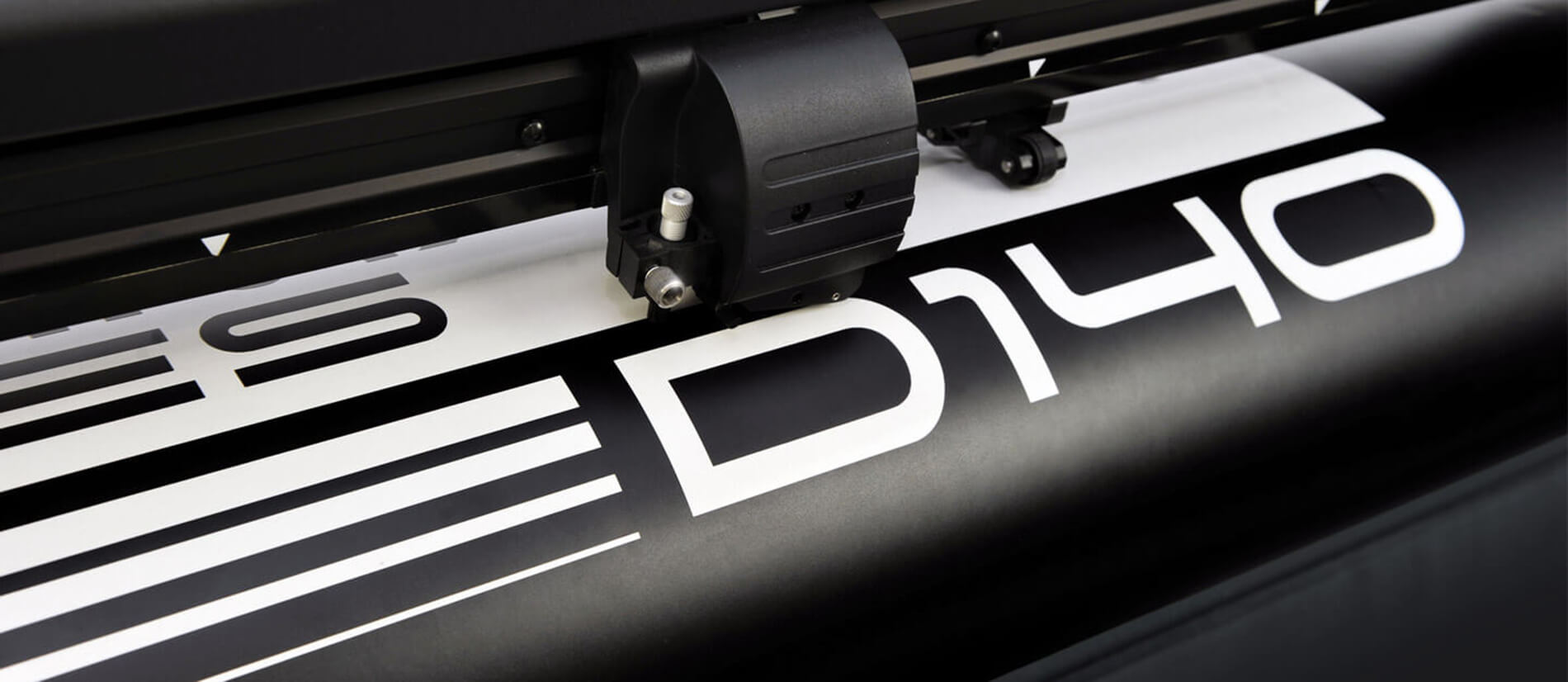

Cutter-plotter cutting is the fast and precise process by which we typically cut stickers and thin films based on a vector design.

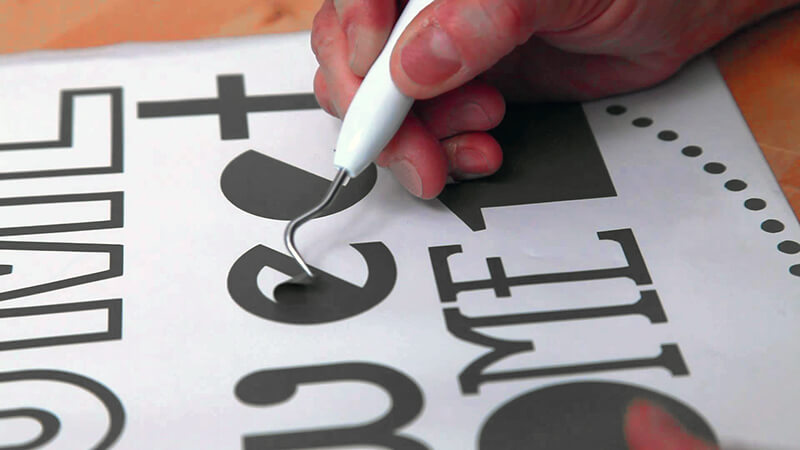

After cutting the sticker films, the areas between the desired elements are removed, and an adhesive film, also known as a transfer film, is applied over it. This film helps transfer the sticker design from the backing paper to the surface where it is intended to be applied.

ou can benefit from cutter-plotter technology either by separately requesting cutting services for your designs or within complex productions that can optimally use these technologies.

The fields of application are diverse, but most often, this technology is used to create self-adhesive special characters for advertising production, including letters and logos for lightboxes, billboards, exhibition stands, showcases, wall stickers, or contour-cut printed stickers.

The materials used for cutter-plotter cutting are usually solid-colored vinyl stickers or printed stickers, aiming to obtain stickers of various shapes and sizes.

The typical working widths for solid-colored self-adhesive materials are 1m and 1.26m, while for special print materials, it can go up to 1.6m.

Thanks to Summa’s TrueTangential™ cutting head, the S2T160 cutter-plotter offers unparalleled cutting precision at a very high working speed.

Using computer-controlled blade rotation and up to 600 grams of cutting force, the Summa S2™ T series cuts better and deeper than any other cutter-plotter in its class, easily handling the cutting of complex and highly detailed graphics.

Files used for cutter-plotter cutting must be prepared in vector format, with fonts converted to curves.

The maximum processing widths depend on the material to be cut, but typically, we can consider a width of 1m.

In the case of sticker cutting, please specify if you want only the material cutting service or if you also want it transferred to a transfer film for better application on the desired